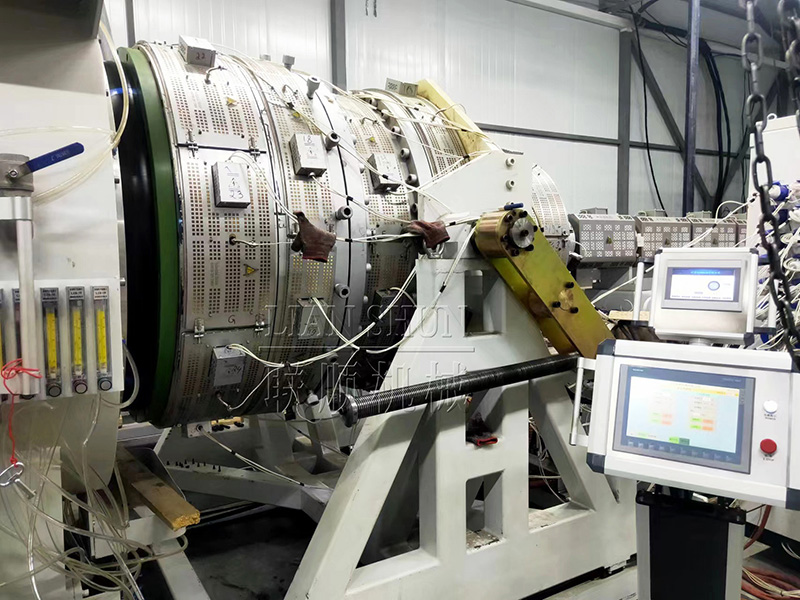

High Speed High Efficient PE Pipe Extrusion Line

wehewehe

Hoʻohana nui ʻia ka mīkini paipu Hdpe no ka hana ʻana i nā paipu irrigation mahiʻai, nā paipu wai, nā paipu kinoea, nā paipu hoʻolako wai, nā paipu conduit a me nā mea ʻē aʻe.

ʻO ka laina extrusion paipu PE he paipu extruder, paipu make, calibration units, cooling tank, haul-off, cutter, stacker/coiler a me nā peripheral āpau. Hoʻopuka ka mīkini hana paipu Hdpe i nā paipu me ke anawaena mai 20 a 1600mm.

Loaʻa i ka paipu kekahi mau hiʻohiʻona maikaʻi e like me ka hoʻomehana ʻana, ke kūpaʻa kūʻokoʻa, ka ikaika mechanical kiʻekiʻe, ke kūpaʻa ʻana o ke kaiapuni i nā māwae, ka maikaʻi creep resistant, etc. Hdpe pipe extrusion machine ua hoʻolālā ʻia me ka extruder kiʻekiʻe a hoʻolako ʻia me ka mea hoʻohaʻahaʻa i kiʻekiʻe ka wikiwiki a me ka haʻahaʻa haʻahaʻa, gravimetric dosing unit a me ultrasonic mānoanoa hōʻailona hiki ke hui ʻia e like me ke koi o ka mea kūʻai aku e piʻi i ka paipu.

Hiki ke hāʻawi ʻia ka hoʻonā kī kī, e like me ka mīkini paʻi laser crusher, shredder, wai chiller, air compressor etc.

Kaʻina Hana

Mea makaʻu + Master Batches → Mixing → Vacuum Feeder → Plastic Hopper Drier→ Single screw extruder → Co-extruder no ke kaula kala & Multi Layers → Mold and calibrator → Vacuum Calibration Tank → Spray Cooling Water Tank → Haul-off machine → ʻoki mīkini → Stacker (Mīkini makani)

Nā hiʻohiʻona a me nā pono

Hoʻokumu ʻia ka mīkini paipu 1.Hdpe e mākou e pili ana i ka ʻenehana holomua ʻEulopa a me ka ʻike R&D o ka mīkini palaki no nā makahiki he nui, ka hoʻolālā kiʻekiʻe, ke ʻano kūpono, ka hilinaʻi kiʻekiʻe, ka automation kiʻekiʻe.

2. Hdpe paipu extruder me kūikawā barela hanai hale hiki nui hoonui extrusion hiki.

3. ʻO ka mana kūpono, ka plasticization maikaʻi, ka hana paʻa.

4. Hoʻohana ka mīkini paipu Hdpe i ka ʻōnaehana mana PLC, ʻike i ka synchronization a me ka automation.

5. He maʻalahi ka hana a ke kanaka-kamepiula, kūpono a hilinaʻi.

6. Ua make ke ʻano hīnaʻi wili a me ka lattice no ke koho ʻana.

7. ʻO ka hoʻololi ʻana i kekahi mau ʻāpana o ka laina hiki ke hoʻomaopopo i ka co-extrusion ʻelua-layer a me multi-layer.

8. ʻO ka hoʻololiʻana i kekahi mau māhele o ka laina hiki ke hana i nā paipu PP, PPR.

Nā kikoʻī

Hookahi Screw Extruder

Ma muli o 33: 1 L/D ratio no ka hoʻolālā wili, ua hoʻomohala mākou i ka ratio 38: 1 L/D. Hoʻohālikelike ʻia me 33: 1 ratio, 38: 1 ratio loaʻa i ka 100% plasticization, hoʻonui i ka mana puka ma 30%, hoʻemi i ka hoʻohana mana a hiki i 30% a hiki i ka hana extrusion linear.

ʻO Simens Touch Screen a me PLC

E noi i ka papahana i kūkulu ʻia e kā mākou hui, loaʻa ka ʻōlelo Pelekania a i ʻole nā ʻōlelo ʻē aʻe e hoʻokomo ʻia i loko o ka ʻōnaehana.

Hoʻokumu ʻāwili o ka Barela

ʻO ka hānai ʻana i kahi ʻāpana o ka barela e hoʻohana i ka hoʻolālā spiral, e hōʻoia i ka meaʻai meaʻai i ka paʻa a hoʻonui pū i ka hiki ke hānai.

Hoʻolālā Kūikawā o ka Screw

Hoʻolālā ʻia ʻo Screw me kahi hoʻolālā kūikawā, e hōʻoia i ka plasticization maikaʻi a me ka hui ʻana. ʻAʻole hiki i nā mea hoʻoheheʻe ʻole ke hele i kēia ʻāpana o ka wili.

Ea hooluu pumehana seramika

ʻO ka mea hoʻomehana seramika e hōʻoia i ke ola hana lōʻihi. ʻO kēia hoʻolālā no ka hoʻonui ʻana i ka wahi e hoʻopili ai ka mea wela me ka ea. No ka loaʻa ʻana o ka hopena hoʻoluʻu ea.

Pahu Kiekie Kiekie

E hōʻoia ʻia ka pololei o ka mīkini 5-6 a me ka leo haʻahaʻa ma lalo o 75dB. Hoʻolālā paʻakikī akā me ka torque kiʻekiʻe.

Extrusion Die Head

Hoʻopili ke poʻo make extrusion i ke ʻano spiral, hoʻonohonoho pono ʻia kēlā me kēia kahawai kahe. Ma hope o ka mālama ʻana i ka wela a me ka hoʻoliʻi ʻana i ke aniani e hōʻoia i ka holo pono ʻana o nā mea. Paʻa ke poʻo make a hāʻawi pū i ke kaomi paʻa, mai 19 a 20Mpa mau. Ma lalo o kēia kaomi, maikaʻi ka maikaʻi o ka paipu a me ka liʻiliʻi o ka hopena i ka mana hoʻopuka. Hiki ke hana i ka paipu papa hoʻokahi a i ʻole ka paipu.

Mea hoʻoneʻe o Die Head

No ke poʻo make nui, hiki i ka mea hoʻoneʻe ke neʻe i ke poʻo make i mua a i hope, hoʻoponopono pū i ke kiʻekiʻe o ke poʻo make. He wikiwiki a maʻalahi ka hana.

Mea Hana Rotary Poʻo Make

No ke poʻo make nui nui me ka mea rotary, hiki ke hoʻololi ke poʻo make ma 90 degere. Ke hoʻololi i ka nahele, mandrel, make poʻo e huli 90 degere. Hiki ke hoʻohana i ka crane e hāpai a hoʻololi i ka nahele a me ka mandrel. He kūpono loa kēia ala.

Mea hoopau wela

Hoʻohui ʻia kēia mea hana ma ke poʻo make e hana i ka paipu nui a manoanoa. E hoʻopau i ka wela i loko o ka paipu a me ka paipu hoʻoluʻu i loko o ka paia. Hiki ke hoʻohana ʻia ka mea wela wela e hoʻomaloʻo i ka mea maka.

Mea hooluolu no Core

I ka hana ʻana i ka paipu me ke anawaena nui a me ka mānoanoa o ka pā, e hoʻohana mākou i ka wai hoʻoluʻu a i ʻole ka aila pū me ka peʻahi hoʻoluʻu e hōʻoluʻolu i ke kumu o ke poʻo make e pale aku ai i ka wela a hōʻoia i ka maikaʻi o nā mea waiwai.

ʻO ka pahu hoʻomāmā

Hoʻohana ʻia ka pahu Vacuum Calibration e hana a hoʻoluʻu i ka paipu, i hiki ai i ka nui o ka paipu maʻamau. Hoʻohana mākou i ka hoʻolālā lumi ʻelua. ʻO ke keʻena mua ma ka lōʻihi pōkole, e hōʻoia i ka hana hoʻoluʻu ikaika loa. Ke kau ʻia nei ka calibrator i mua o ke keʻena mua a ua hoʻokumu ʻia ke ʻano paipu e ka calibrator, hiki i kēia hoʻolālā ke hōʻoia i ka wikiwiki a ʻoi aku ka maikaʻi o ka hoʻokumu ʻana o ka paipu.

ʻO ka hoʻoluʻu ikaika no ka Calibrator

Me ka ʻōnaehana hoʻoluʻu kūikawā no ka calibrator, hiki ke loaʻa ka hopena hoʻomaha maikaʻi no ka paipu a hōʻoia i ka wikiwiki kiʻekiʻe. Me ka nozzle spray maikaʻi maikaʻi e loaʻa ai ka hopena hoʻomaha maikaʻi a ʻaʻole maʻalahi ke kāohi ʻia e nā haumia.

Kākoʻo maikaʻi no ka Pipe

No ka paipu nui, loa'a i kēlā me kēia nui kona papa kāko'o semicircular pono'ī. Hiki i kēia hale ke mālama pono i ka pōʻai paipu.

Mea hāmau

Hoʻokomo mākou i ka silencer ma luna o ka pahu hoʻoponopono ʻūhā e hōʻemi i ka walaʻau ke komo ka ea i loko o ka pahu pahu.

Paʻi Paʻi Paʻi

No ka pale ʻana i ka pahu hau. I ka hiki ʻana i ka palena kiʻekiʻe loa, e wehe koke ka valve e hoʻemi i ka degere vacuum e pale aku i ka haki ʻana o ka pahu. Hiki ke hoʻololi ʻia ka palena palena ʻole.

Paipu Loop Lua

ʻO kēlā me kēia loop me ka ʻōnaehana kānana wai, e hāʻawi i ka wai hoʻomaha maʻemaʻe i loko o ka pahu. Hoʻopaʻa pū ka lua lua i ka hāʻawi mau ʻana i ka wai anuanu i loko o ka pahu.

Wai, Hoʻokaʻawale Gas

E hoʻokaʻawale i ka wai wai kinoea. Ua pau ke kinoea mai luna. Kahe ka wai i lalo.

Hoʻoholo wai ʻakomi piha

Me ka hoʻomalu wela mechanical e loaʻa ka mana pololei a paʻa o ka mahana wai.

Hoʻomalu ʻia ka ʻōnaehana inlet a me ka puka wai piha piha, kūpaʻa a hilinaʻi.

Mea hoʻoheheʻe wai kikowaena

Hoʻohui ʻia nā hoʻoheheʻe wai a pau mai ka pahu ʻawaʻawa a hoʻopili ʻia i hoʻokahi pipeline stainless. E hoʻopili wale i ka pipeline i hoʻohui ʻia i ka hoʻoheheʻe ʻana i waho, i mea e maʻalahi a wikiwiki hoʻi ka hana.

Pahu wai hooluolu

Hoʻohana ʻia ka pahu hoʻoluʻu e hoʻoluʻu hou i ka paipu.

Mea Paipu Paipu

Hiki i kēia mea hana ke hoʻololi i ka pōʻai paipu i ka wā e puka mai ai ka paipu mai loko mai o ka pahu pahu.

Kānana pahu wai

Me ka kānana i loko o ka pahu wai, e pale aku i nā haumia nui ke komo ka wai o waho.

Nozzle Spray Pono

ʻOi aku ka maikaʻi o ka hopena hoʻoluʻu maikaʻi a ʻaʻole maʻalahi ke kāohi ʻia e nā haumia.

Paipu Kākoʻo Hoʻoponopono Mea Hana

Kākoʻo me ka hana hoʻoponopono e kākoʻo i ka paipu me nā anawaena like ʻole.

Mea kākoʻo paipu

Hoʻohana nui ʻia i ka hana ʻana i ka paipu me ke anawaena nui a me ka mānoanoa o ka paia. Hāʻawi kēia mea hana i ke kākoʻo hou i nā paipu kaumaha.

Mīkini Haul Off

Hāʻawi ka mīkini hoʻokuʻu i ka ikaika huki e huki pono ai i ka paipu. E like me ka nui o ka paipu a me ka mānoanoa, e hana kā mākou hui i ka wikiwiki traction, ka helu o nā maiuu, ka lōʻihi o ka traction. No ka hōʻoia ʻana i ka wikiwiki extrusion paipu a me ka wikiwiki o ka hoʻokumu ʻana, e pale pū i ka deformation o ka paipu i ka wā traction.

Mokini Hoʻokaʻawale

Loaʻa i kēlā me kēia maiuu kāna kaʻa kaʻa ponoʻī, i ka wā i pau ai ka hana ʻana o kekahi kaʻa kaʻa, hiki ke hana nā kaʻa ʻē aʻe. Hiki ke koho i ka mīkini servo e loaʻa i ka ikaika traction nui, ʻoi aku ka paʻa o ka traction wikiwiki a me ka laulā o ka wikiwiki traction.

Mea Hoʻoponopono Maʻuuu

Hoʻopili ʻia nā maiuu a pau i kekahi i kekahi, ke hoʻololi i ke kūlana o nā maiuu e huki i ka paipu ma nā ʻano nui like ʻole, e neʻe like nā maiʻu a pau. E hana wikiwiki a maʻalahi kēia hana.

Hoʻolālā hoʻohana

Me nā lako paʻakikī Siemens a me nā polokalamu hoʻohana i hoʻolālā ʻia e kā mākou hui. Loaʻa i ka hana synchronized me extruder, e hana maʻalahi a wikiwiki hoʻi. Hiki nō hoʻi i ka mea kūʻai ke koho i kekahi mau maiuu no ka huki ʻana i nā paipu liʻiliʻi.

Hoʻokaʻawale i ke ea kaomi

ʻO kēlā me kēia maiuu me ka mana kaomi ea, ʻoi aku ka pololei, ʻoi aku ka maʻalahi o ka hana.

. ʻO ka ikaika huki kiʻekiʻe me ka nalowale ʻole o ke ʻano o nā paipu

. Hoʻolako ʻia me 2, 3, 4, 6, 8,10 a i ʻole 12 enuhe e like me ka noi.

. ʻO ka hoʻokele kaʻa Servo no ka hāʻawi ʻana i ka torque paʻa a me ka holo

. Ke hoʻonoho ʻia ʻana o nā enuhe haʻahaʻa

. Hana maʻalahi

. Paʻa paʻa loa no ka palekana kiʻekiʻe

. ʻO nā mea hoʻoili kaulahao me nā pad kopa kūikawā ma nā kaulahao ʻaʻohe māka ma ka paipu.

. ʻO ka synchronization me ka extruder screw speed hiki ke hana paʻa i ka wā e hoʻololi ai i ka wikiwiki hana

Mīkini ʻoki paipu

ʻO ka mea ʻoki paipu plastik i kapa ʻia hoʻi ka mīkini ʻoki paipu i hoʻomalu ʻia e Siemens PLC, e hana pū ana me ka ʻāpana haul off e loaʻa ka ʻoki pololei. Hiki i ka mea kūʻai ke hoʻonohonoho i ka lōʻihi o ka paipu a lākou e makemake ai e ʻoki. ʻO nā hana hoʻohuihui nui no ka hoʻokō ʻana i ke kaʻina ʻoki hoʻokahi (pale i nā ʻili a me nā ʻoki, pale i ka ʻili a me nā ʻili i paʻa no ka paipu mānoanoa a maʻemaʻe ka maka o ka paipu).

Mea Paʻi Paʻi Universal

E hoʻopili i ka mea hoʻopili paʻa honua no nā nui paipu like ʻole, ʻaʻohe pono e hoʻololi i ka mea hoʻopili i ka wā e loli ai ka nui o ka paipu.

Hiki ke hoʻololi i ka Saw a me ka Blade

Hoʻolako ʻia kekahi mau ʻokiʻoki me ka ʻili a me ka maka. Hiki ke hoʻololi ʻia ka ʻike a me ka ʻoki ʻana no nā nui paipu like ʻole. Eia kekahi, hiki ke hana pū ka ʻike a me ka pahi no nā koi kūikawā.

Hoʻoponopono kiʻekiʻe waena

Me ka mea hoʻoponopono uila no ka mea hoʻopili. ʻOi aku ka wikiwiki a me ka maʻalahi o ka hana. Me ka hoʻololi palena e hōʻoia i ka palekana.

. Hoʻonohonoho ʻakomi me ka wikiwiki extrusion

. Hoʻolako ʻia ka Planetary me ka disk a me ka mea ʻoki wili no ka ʻoki a me ka chamfering

. Hoʻolako ʻia ʻo Chip-free me ka disk blade e hōʻoia i ka ʻoki ʻana i ka ʻili me ka lepo ʻole

. Pākuʻi hoʻomalu panel

. ʻO nā neʻe a pau e hoʻokele ʻia a hoʻokele ʻia e ka panel mana

. Paʻa paipu me ka hoʻohana ʻana i ka hoʻopili honua no ka hana maʻalahi

. ʻOi aku ka pono o ka mālama ʻana

. ʻO ka mīkini paʻa a hoʻopaʻa ʻia no ka palekana kiʻekiʻe

Hoʻopaʻa

E kākoʻo a wehe i nā paipu. Hiki ke hoʻopilikino ʻia ka lōʻihi o ka stacker.

Pale ili paipu

Me ka huila, e pale i ka paipu i ka wā e neʻe ai i ka paipu.

Hoʻoponopono kiʻekiʻe waena

Me ka mea hoʻoponopono maʻalahi e hoʻoponopono i ke kiʻekiʻe waena no nā nui paipu like ʻole.

ʻO ka huila

E wili i ka paipu i loko o ka roller, maʻalahi no ka mālama ʻana a me ka lawe ʻana. Hoʻohana maʻamau no ka paipu ma lalo o ka nui 110mm. Loaʻa i kahi kikowaena hoʻokahi a me kahi kikowaena pālua no ke koho.

Ka hoʻohana ʻana i ka mīkini servo

Hiki ke koho i ka mīkini servo no ka neʻe ʻana o ka paipu a me ka wili, ʻoi aku ka pololei a ʻoi aku ka maikaʻi o ka neʻe ʻana o ka paipu.

ʻIkepili ʻenehana

| Laulā anawaena(mm) | Hoʻohālike extruder | Max. Kaha (kg/h) | Max. laina laina (m/min) | Mana Extruder (KW) |

| Ф20-63 | SJ65/33 | 220 | 12 | 55 |

| Ф20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Pālua | SJ60/38 | 460 | 15×2 | 110 |

| Ф20-110 | SJ65/33 | 220 | 12 | 55 |

| Ф20-110 | SJ60/38 | 460 | 30 | 110 |

| Ф20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| Ф1000-1600 | SJ 90/38 SJ 90/38 | 1,900 | 0.6 | 280 280 |